tell northeast:

uncovering regional stories worth sharing.

Meet the Maker: Ploughgate Creamery

The Resurrection Of A Butter Farm

Words and Photographs by Emily Nichols

There is a farm in Fayston, Vermont whose vistas have been featured in many a postcard. The outlook offers sweeping views of the Mad River Valley, includingSugarbush’s two peaks engraved with ski trails. This is Bragg Farm where Marisa Mauro makes small-batch, cultured butter. Until recently Marisa had no idea that she is reviving a hundred-year old tradition on these grounds.

When I first met Marisa she had already started and lost her first successful small business. That operation was Ploughgate Creamery, located in Vermont’s Northeast Kingdom. For three years she produced award-winning cheeses* until a fire in September 2011 destroyed her facility. She was 26 years old. Following the loss, Marisa took a break from the dairy industry and didn’t have plans to return.

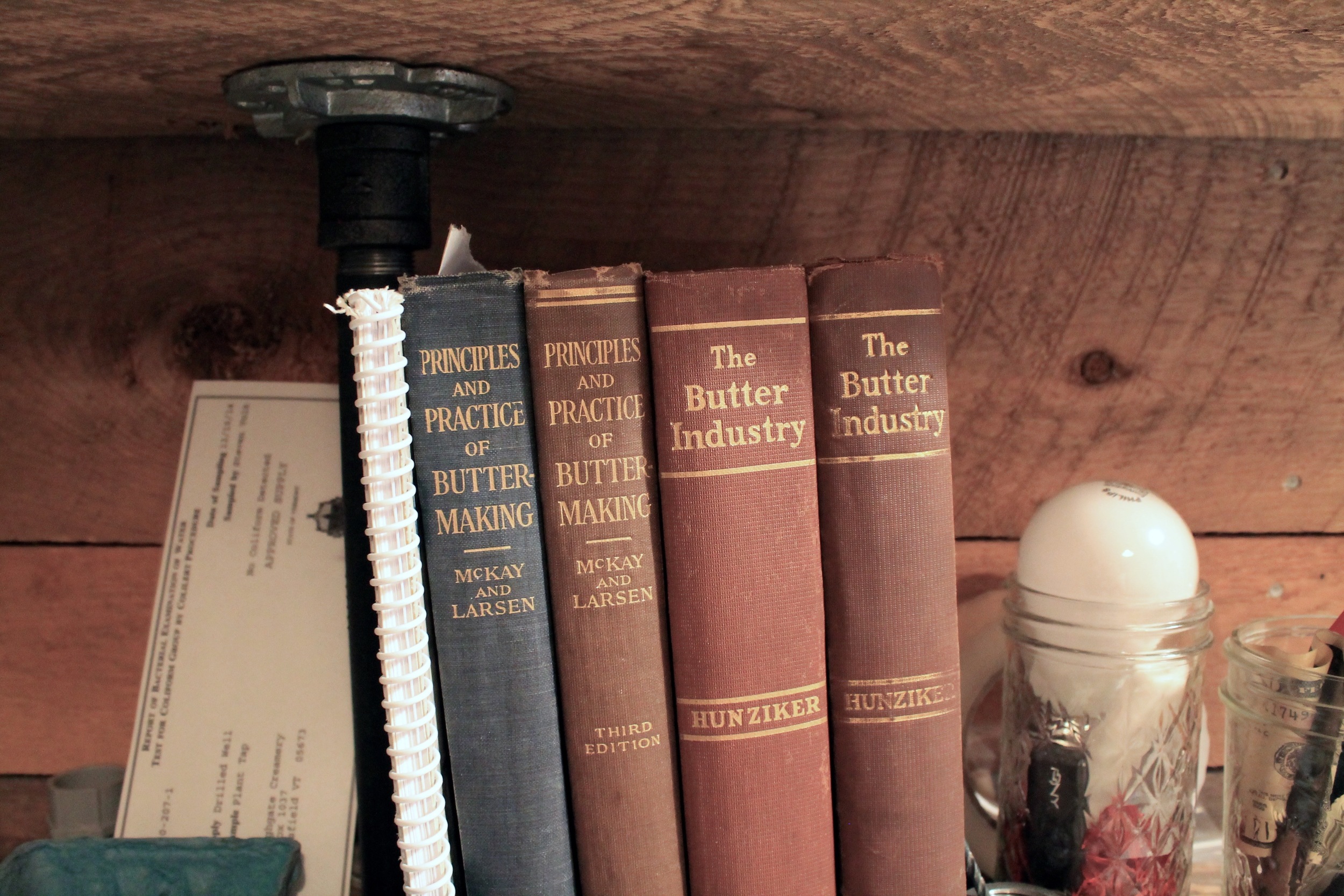

Enter Bragg Farm. Marisa was waitressing when a friend notified her that the Vermont Land Trust had purchased an historic property in Fayston. They would resell it for its agricultural value to the entrepreneur with the best plan. Marisa visited the property and was immediately inspired to apply. Resurrecting her cheese operation would have been the obvious choice but she was ready for a new challenge. “I had been making cheese since I was 15,” says Marisa, and “when I began to do research I found that little had been written on butter-making in a very long time. There also didn’t appear to be much equipment for small to medium size producers left in the U.S.”. While artisan cheese production in New England was thriving, butter was being neglected. Marisa drafted a 30-page business plan and entered a pool of thirteen candidates vying to take ownership of Bragg Farm. Like cream from milk, Marisa rose to the top and was awarded that opportunity in December 2013.

It was only after Marisa had moved to the farm that she met fellow Vermonter, Doug Bragg, owner and sugarmaker of The Bragg Farm Sugarhouse in East Montpelier. Doug is the great, great grandson of Azro and Anna Bragg, the first in a long line of Braggs to own the Fayston property (and bestowers of the farm’s namesake). It turns out Azro and Anna also made butter, and lots of it. Carefully preserved letters from Bragg family members tell of butter that was hand-churned from the milk of forty cows and transported to Boston by way of wagon and train. It’s fitting symmetry that a century later Marisa’s butter

travels the same route.

Marisa also learned from Doug that it was Azro’s and Anna’s son Frank who raised the property’s iconic bank-style barn in 1909. All the lumber for the project was milled from the surrounding forests during the winter of 1908. On June 12, 1909 a small army of locals participated in framing the structure. Since then it has seen intermittent periods of activity and idle. Until Marisa, Bragg Farm had not been used as a dairy enterprise since the early 1970s. Without the Vermont Land Trust’s conservation efforts changing that trajectory it likely would have remained that way.

Resurrecting the farm from a forty-year hiatus delivered the challenge Marisa sought. Her first year was spent on construction projects, equipment sourcing, and recipe testing. Each presented its own roadblocks. As her initial research foretold, little equipment matching the scale of her vision was available. Undeterred, Marisa patched together a solution. She purchased a churn from Wisconsin and a separator from Ukraine. The latter she had modified in Maine to meet U.S. standards. By last summer Marisa was up and running, churning out her first butter batches for local farmer’s markets.

Cultured butter is tangier and richer than your everyday stick butter, with a taste reminiscent of cheese. That’s because cultured butter and cheese share a critical first step – the addition of beneficial live bacteria (the ‘culture’ in cultured butter). All Ploughgate Creamery butter begins as pasteurized cream from a dairy cooperative in St. Albans, Vermont. To begin a butter make, Marisa adds active cultures to the cream and lets it sit for 48 hours. This imparts complexity to the aroma, flavor, and texture of the finished product. After two days it’s time to churn. Gratefully the days of hand churning are long gone, and Marisa’s industrial churn does the work of separating the pale yellow butterfat from the frothy buttermilk. A drain on the underbelly of the churn releases the buttermilk into a five-gallon bucket. A mason jar’s worth is saved to make salad dressings; the rest is fed to Marisa’s pigs. Finally Marisa folds in sea salt by hand before wrapping the butter into tidy half and one-pound packages. The end result is nutty, grassy, and sweet – simply divine.

With Marisa at the helm, Bragg Farm and Ploughgate Creamery have revived each other. Our landscape, our community, and our toast are better for it.

Where to find Ploughgate Creamery butter:

- Formaggio Kitchen (Cambridge, MA)

- Rubiner’s (Great Barrington, MA)

- City Market (Burlington, VT)

Find Ploughgate Creamery online at www.ploughgate.com

*Lucky for us, Marisa’s cheese-making legacy lives on. Following the 2011 fire, Jasper Hill Farm in Greensboro bought the rights to Marisa’s recipe for Willoughby, a washed-rind cow’s milk cheese.

Emily Nichols writes the food blog www.hungryinlove.com, celebrating seasonal recipes from New England and beyond.